From student project to everyday tool: Automating truss joint calculations

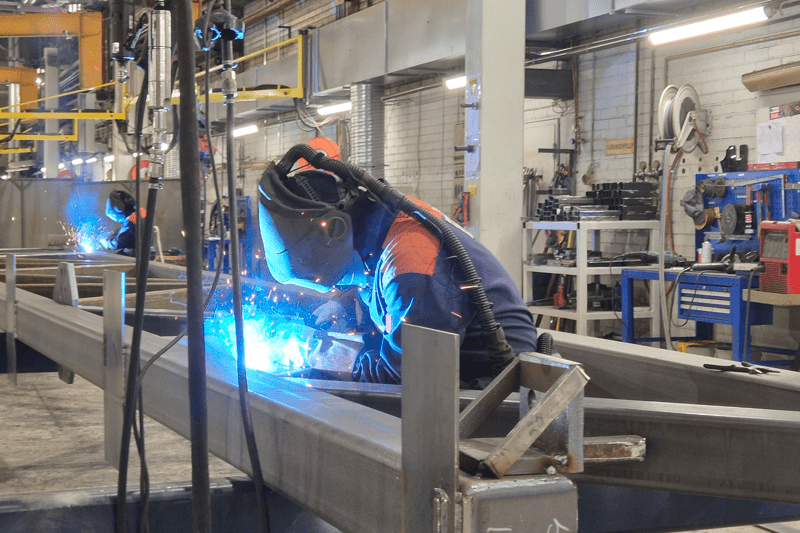

A routine calculation task that once took several hours now takes only minutes. The change comes from a thesis project by Design Engineer Lukas Aarnio, who developed an automated method now used across Nordec’s project teams. SCIA Engineer, a structural analysis program widely used in steel construction, provided the framework for integrating the improvement directly into the design environment.

Practical thesis cooperation

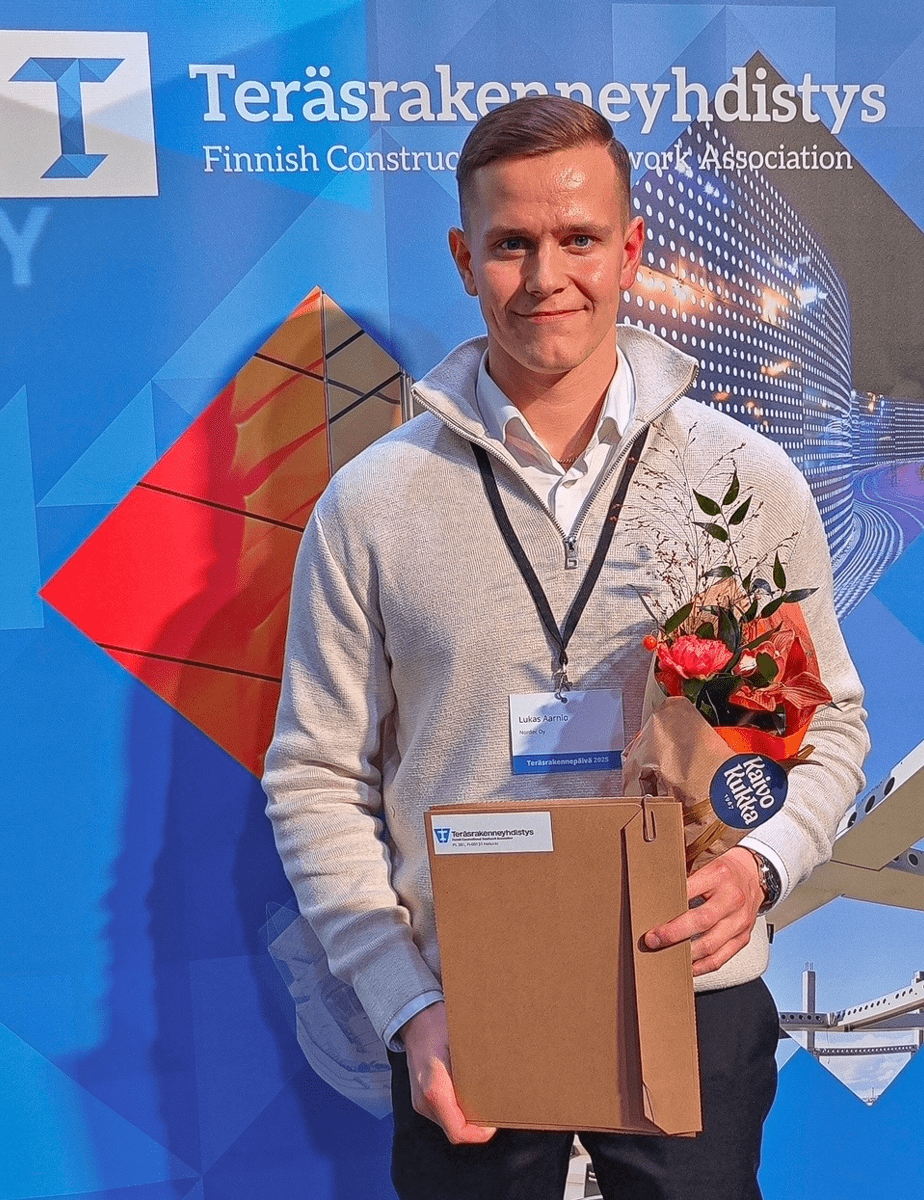

Lukas completed his thesis in 2025 while working in Nordec’s structural design organization. Earlier temporary roles had already shown him where everyday efficiency could be improved. The thesis topic came from his Nordec supervisor, Rickard Nybacka, who had identified a clear need to streamline how truss joint calculations were handled. Nordec supported the project with supervision, tool access, and regular early-stage guidance.

The limitations of the previous workflow became clear early in the work. Excel was not feasible due to the complexity of data transfer and the number of manual steps required. “Once that became clear, building the tool directly inside SCIA was the logical step,” Lukas explains. “Developing something that designers can apply in real work felt worthwhile.”

During the first two months of the thesis work, Lukas and Rickard Nybacka met online weekly to review progress and resolve technical issues. After the early phase, communication shifted to shorter meetings and email, allowing the thesis to advance independently while still ensuring continuity.

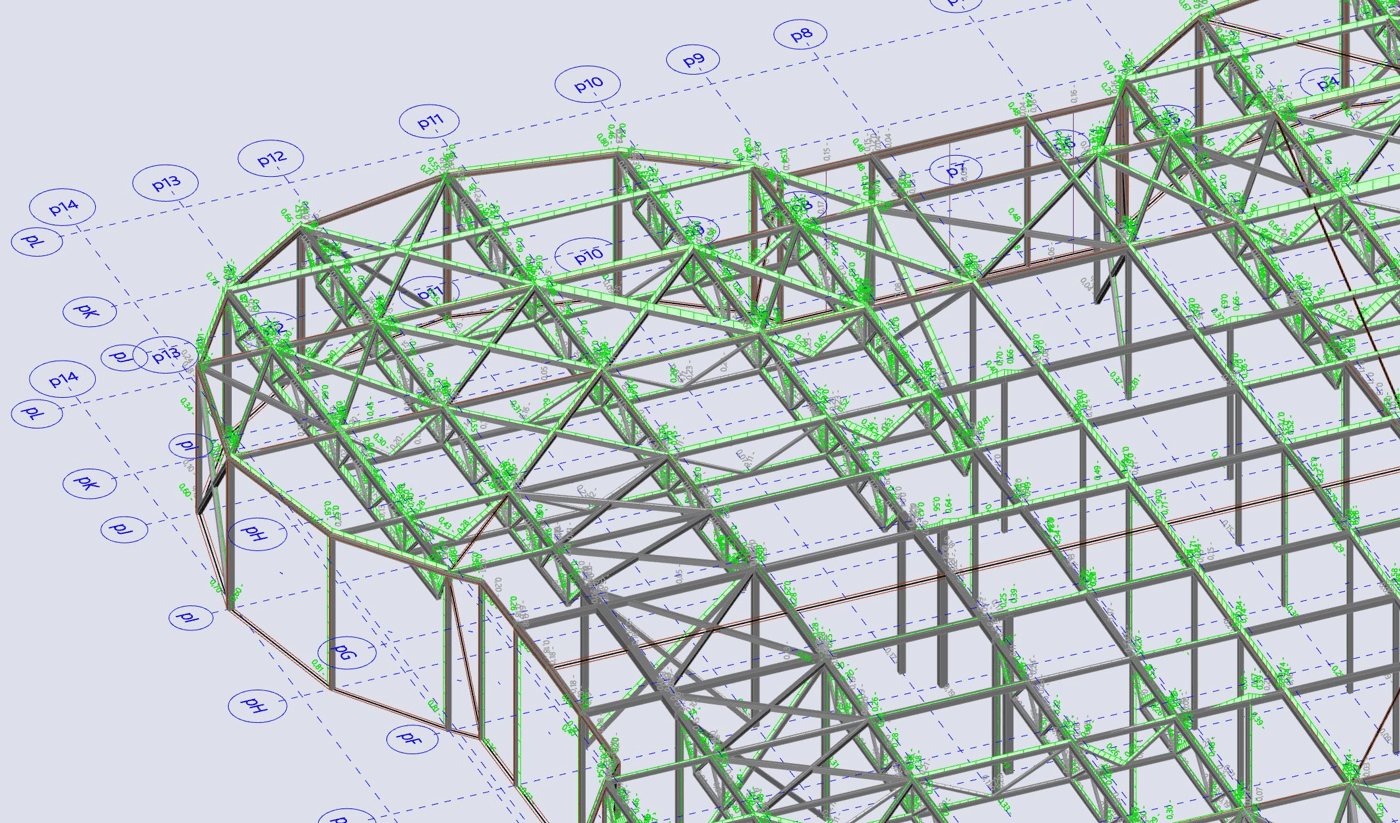

Automating truss joint calculations inside SCIA Engineer

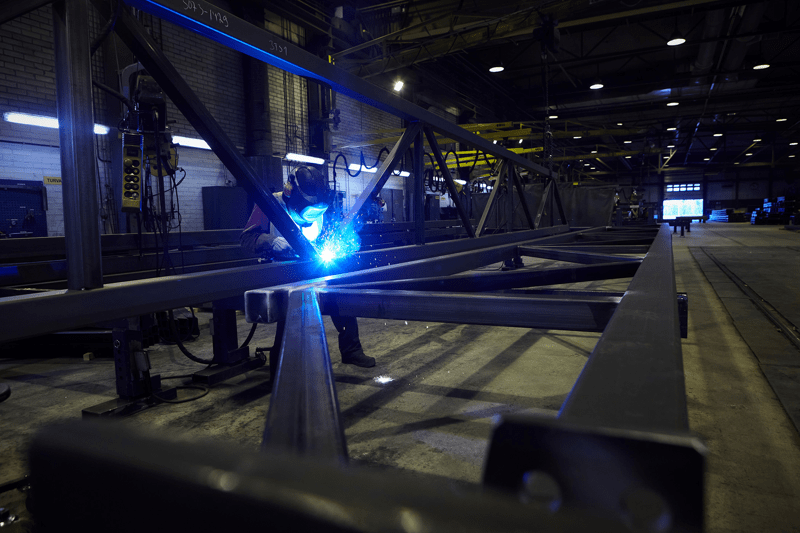

The final solution uses model data already available in SCIA and performs the required checks automatically. This removed the need to switch between programs and reduced manual data handling. Validation against earlier Excel-based results confirmed that the method worked as intended. A process that previously took four hours could now be completed in about five minutes. Automating the inputs also lowers the risk of manual errors, improves consistency between designers and supports large projects where many similar joints must be checked systematically.

The tool is already part of Nordec’s design workflow and has supported several ongoing projects. According to Nordec supervisor Rickard Nybacka, the cooperation benefits both the company and the student. “Automating this workflow removes repetitive steps and supports consistent results across projects. Thesis cooperation gives students a chance to work with real engineering challenges while producing tools we can apply directly in our design work.”

This reflects Nordec’s approach to practical development. Thesis projects are linked to real engineering needs, giving students experience with industry-level challenges and contributing solutions that support the wider organization.

Lukas’s thesis received a Recognition Award at Teräsrakennepäivä, the annual event organized by the Finnish Constructional Steelwork Association. For him, the recognition confirmed the relevance of the topic. “It showed that automation in structural engineering is an important theme and that improving everyday workflows matters,” he says.

The cooperation around this thesis shows how practical development work can lead to tools that genuinely support daily design tasks. The result is a small but measurable improvement that is already in use and continues to benefit project teams. Nordec will keep focusing on digital solutions that strengthen this kind of everyday efficiency in steel construction.

More about Teräsrakenneyhdistys and Scia Engineer.